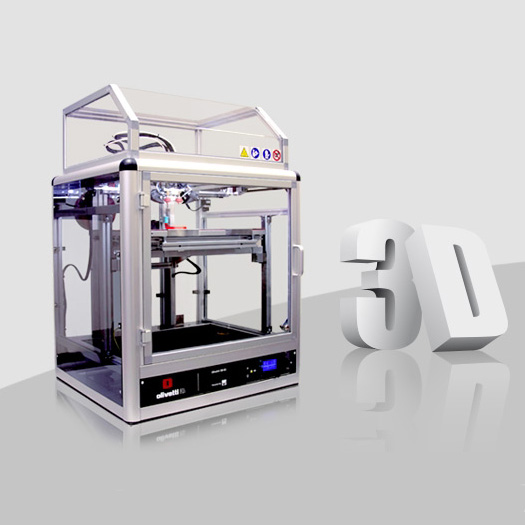

Olivetti 3D S2

Olivetti 3D S2

3D Printer - Olivetti S2 - 3D Print reliable with dual extruder

Olivetti 3D-S2 is the 3D printer specifically designed for small to medium-sized enterprises engaged in the digital transformation process. With its large format printing capacity (up to 400x400x400 mm) and the high printing speed (over 150 mm/sec) the Olivetti 3D-S2 is one of the best performing 3D printers in its reference category, allowing objects of even considerable dimensions to be built quickly.

- Industrial quality and reliability

- Large format printing area

- Various plastic materials worked – also filled-up with wood, plastic, carbon and marble

- Direct printing from sd card possible without use of pc

- Dual extruder

More info: Contact us

3d Printer - Olivetti S2: the best solution for your 3D printing

The 3D printing and rapid prototyping have become two activities necessary to the industrial development of a business. The ease with which the prototypes are produced compared to a few years ago has enabled many small businesses to become independent in the digital transformation of models. Olivetti S2 3D printer allows in short times and with complete reliability to build perfect models thanks to its large format print area and processing of various plastic materials. One of the most important features is the double extruder which allows more printing speed and a reduction of the breaks.

Rapid Prototyping thanks to 3d printer - Olivetti S2

The rapid prototyping is a technique for the realization of prototypes that is based on the addition of plastic material through a spray effect that allows the creation of prototypes of any shape and complexity.

ADVANTAGES

- One of the biggest printing areas - The printing area (40 x 40 x 40 cm) increases the possibilities of use within the company, to fulfil every need!

- Full compliance with the quality and safety certifications and Regulations - Olivetti S2 has passed all tests required by the Machinery Directive (2006/42/EC), for the full protection and safety of persons in the product life cycle different stages.

- Mechanical and electronic industrial-strength quality - Olivetti S2 is able to manage heavy workloads and it is particularly suitable for a professional use.

- Great flexibility in creating objects with a wide range of thermoplastic materials - wide range of thermoplastic materials including: PLA, PLA Layer, Rubber (TPU), SBC, special filaments (wood filament, carbon-fiber filament, marble filament)

- Dual Extruder - Thanks to the dual extruder, Olivetti S2 allows

- better realization and finishing of items with form "cantilever", by printing the support with soluble material

- printing of two-colored and / or formed from two different materials objects, without the need to suspend the printing to change the filament

- Fused Filament Fabrication (FFF)

- Printing area 400x400x400 mm, one of the largest in the category

- Anodized aluminum shell 45x45 mm radiated

- Polycarbonate paneling

- Closed Structure body, with front panel lock

- Dual extruder

- Tempered glass big heatbed

- Direct printing from a SD card without using the PC

- Print speed 150 mm/s

- Minimum layer thickness: 0.05 mm (50 microns)

- Printer nozzles in different diameters: from 0.30 mm to 0.80 mm

- Integrated LCD control panel

The Olivetti S2 has a front 128x64 dot matrix LCD display. Here are the main printer operations controls that can be managed through the display:

- First nozzle temperature

- Second nozzle temperature

- Heatbed temperature

- Cooling fan speed

- Nozzle current position (X, Y, Z)

- Selected Feed Rate

- Print progress from SD card

- Printing time

- The status bar (status messages, and/or error messages)

- Printing area 400x400x400 mm

- Printing volume: about 64 liters

- Minimum layer thickness: 0.05 mm (50 microns)

- Precision tolerance (net of material retraction)

- X-y axis: 0.08 mm (80 microns)

- Z axis: 0.01 mm (10 microns)

- Maximum extruder temperature: 285 ° C

- Maximum heatbed temperature: 120 ° C

- Filament diameter: 1,75 mm

- The Olivetti S2 can produce objects using filaments of a wide range of thermoplastic materials, including PLA, ABS, nylon, rubber (TPU),

- However, the use of non-certified filaments could cause the extruders’ and nozzles’ clog, with consequent interruption of the operations and possible replacement of some components

For this reason, we suggest the use of Olivetti filaments to guarantee the printer correct operations and the best quality of printed items.