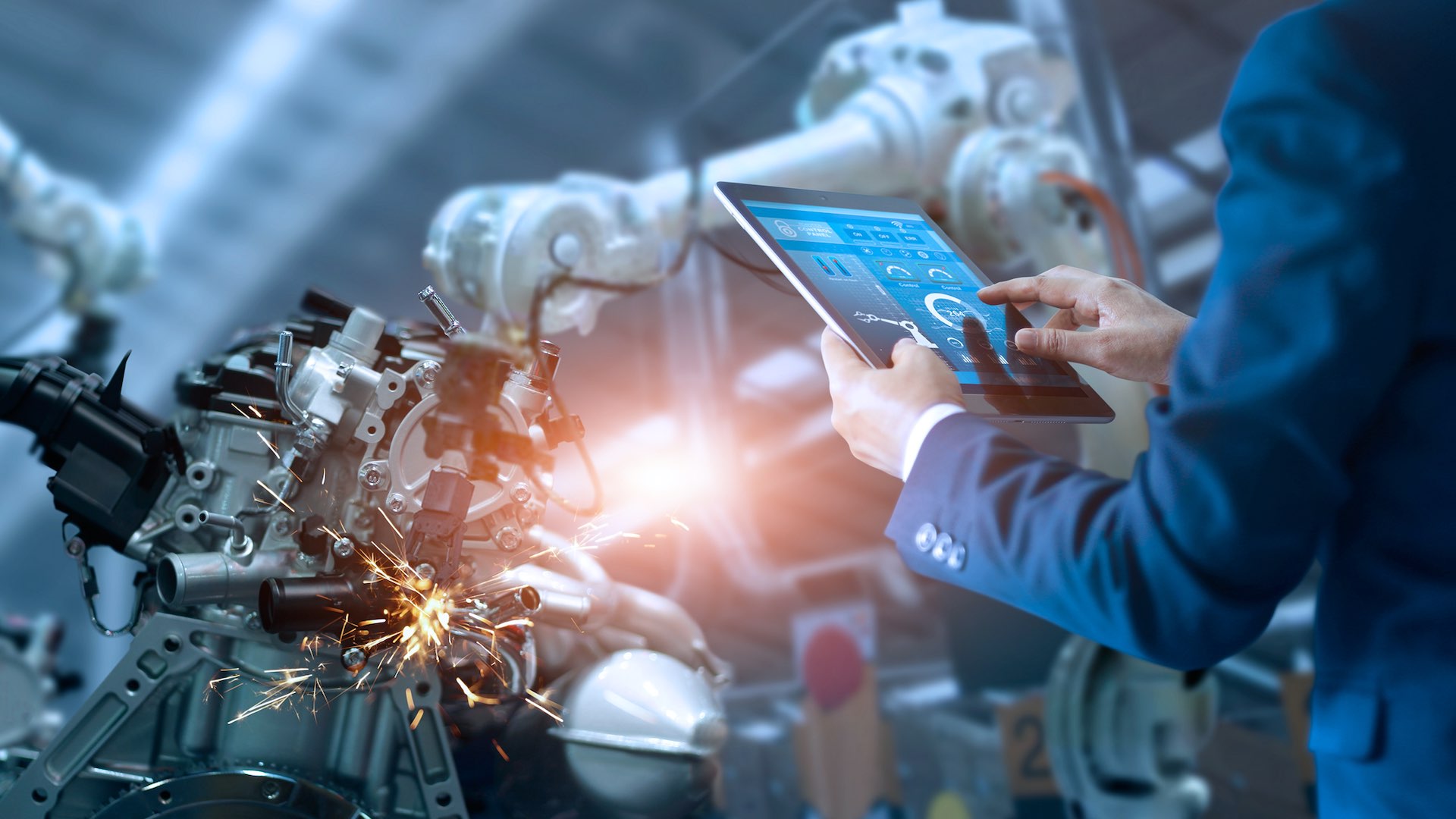

Smart Factory 4.0 and M2M Smart solutions allow the integration of heterogeneous machines and the acquisition of data necessary for improving maintenance activities on production lines. Tommaso Cornaglia: "Knowledge and data processing are crucial assets for any company". Alleantia is also a player .

The potential is enormous, and the game remains still to be played. The Italian Internet of Things market is in full swing and it is the "Industrial" segment that is registering the highest growth rates, particularly thanks to government measures relating to the Business Plan 4.0. According to the latest findings of the Industry 4.0 Observatory, School of Management, Milan Polytechnic, it is Industrial IoT (i.e. components for connecting machines to the network) that takes the lion’s share: in 2018 (latest available figures) it generated a value of €1.9 billion, representing 60% of the market, and showed the most marked growth year after year (+ 40%). Industrial Analytics comes second with €530 million and a market share of 17% (+ 30%), followed by Cloud Manufacturing with €270 million equal to a market share of 8% (+ 35%). Roughly 800 4.0 applications are registered in Italy, on average four per company. Fully operational projects - stresses Polimi - have produced greater operational flexibility and lower management costs.

Italian best practices – Cornaglia Group

Italian companies are therefore gradually awakening to the opportunities offered by 4.0. There are already some that can be counted amongst best practices, both in terms of the types of projects launched and the results and objectives achieved. Amongst these is the Cornaglia Group, an Italian company engaged in the supply of systems for automotive, trucks and off-road sectors. After introduction of a new MES (Manufacturing Execution System), the company successfully integrated heterogeneous machines and acquired the data necessary for improving maintenance activities related to production lines. "Knowledge and data processing are fundamental assets for all companies today", explains Tommaso Cornaglia, Group Controller of Cornaglia, whose attention is focused on the issue of digitally transforming the company, the project’s springboard.

Tim and Olivetti, partners in the digital transformation

Tim and Olivetti are the technological partners engaged in the project: Smart Factory 4.0 and M2M Smart solutions have been deployed for managing the sending and reception of production data from the three company factories. The technological heart of the offer is composed of software and connectivity components providing IoT gateways and interfaces with the new MES system. All this in continuity with data center networking and virtualization projects already in progress with Tim.

Solutions deployed

The project has seen also Alleantia as a key player, an Italian company that owes its success to a line of Industry 4.0 "Plug & Play" solutions with the power to accelerate the digital transformation of industries. “We needed to embark on the digital transformation of our group and, thanks to the solution proposed by Tim, Olivetti and Alleantia, we have succeeded in resolving this issue in an incredibly fast, efficient way", explains Cornaglia.

Adoption of Smart Factory 4.0 solutions – of which Alleantia ISC software forms an integral part – and M2MSmart solutions allowed the Cornaglia Group to integrate data generated by diverse systems and to implement predictive maintenance thanks to aggregate data management and real-time vision of all production data. “Olivetti Smart Factory 4.0 – emphasises Giuseppe Sola, Head of Sales, Olivetti Digital Services – has responded to the need for a faster, scalable, flexible Industrial IoT able to support the integration of heterogeneous machines and the acquisition of large quantities of data necessary for plant maintenance and monitoring activities. For the Cornaglia Group, we have followed the full delivery roll-out including hardware, software, customer training and after-sales assistance”.