Olivetti 3D DESK

Olivetti 3D DESK

The printer 3D DESK is designed for schools, universities and professional firms requiring a compact 3D printer with optimal levels of performance and reliability.

The totally enclosed structure provides maximum safety during use, while the compact footprint and fast speeds (reaching up to 200 mm/sec) make the Olivetti 3D DESK the ideal solution for transforming fast and economically a three-dimensional drawing into its realistic physical version.

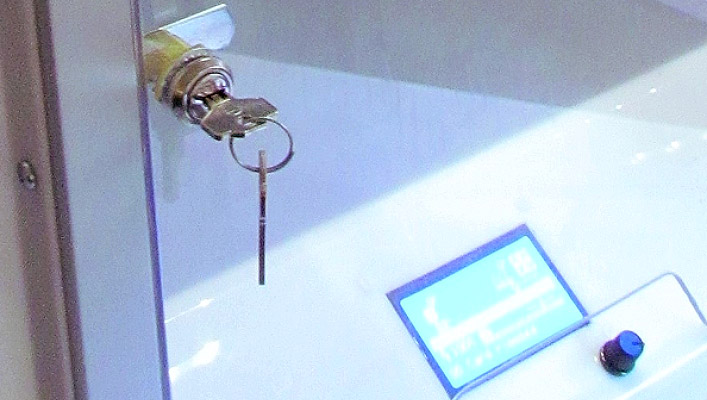

- Fully enclosed structure with door lock for maximum safety during use

- Compact dimensions and printing area 200 mm x 200 mm x 200 mm, appropriate to the typical needs of a school and professional context

- Full compliance with the safety rules and with the quality and safety certifications - Olivetti 3D printers are subjected to all the tests required by the European regulations to guarantee the operator safety. The Olivetti 3D DESK is full compliant with the European Directives EMC, Machinery Directive, LVD and ROHS (2006/42/EC), as certified by the presence on the CE marking printer

- Industrial level quality and reliability: mechanical and electronic quality industry standards enable the 3D DESK printer to withstand even heavy workloads, and make it particularly suitable for a professional use and for scholastic environments.

- Safety and high-performance: the ideal 3D printer for creative workshops in schools

- Variety of plastic materials worked

- Interchangeable nozzles - The nozzle can be removed and replaced by the user. This feature allows to vary the diameter of the nozzle expanding the user options.

More info: Contact us

ADVANTAGES

- Compact footprint, full compliancy with safety standards, industrial level quality and highly accurate printing.

- Compact dimensions with a suitably sized printing area for visualising 3D models. The printing area of 200 mm x 200 mm x 200 mm is perfectly suited to the typical needs of schools and professional firms.

- Full compliancy with Normatives and Certifications related to quality and safety criteria. The Olivetti 3D DESK has passed all technical testing required by EC Standards to ensure that users are fully protected during all phases of the product life cycle. Conformity with the Machinery Directive (2006/42/EC) guarantees maximum safety for educational and professional environments.

- Robust structure, high-precision workings, industrial standard engineering and electronic quality - features allowing the 3D DESK to handle also heavy workloads, making it also suitable for professional and other environments – such as schools and educational establishments – where particular robustness is essential.

- Flexibility - objects can be created in a variety of thermoplastic materials amongst which PLA, PLA Hiqh Quality and Special Filaments (e.g. wood charged).

- The closed body structure ensures adequate safety for users and for all persons who might have access to the machine, considering the high operating temperatures reached by 3D printers (particularly in extruders, where the temperature can exceed 200 ° C). The closed body prevents improper access to the print area, thanks also to the panel lock on the front door. The Olivetti 3D DESK was designed and built to provide maximum protection for the user, which is a primary need especially at school!

- Fused Filament Fabrication (FFF)

- Printing Area 200 x 200 x 200mm

- Anodized aluminium body, 30 x 30mm radial

- Panels in polycarbonate

- Single extruder

- Direct printing from SD card possible without PC

- Printing speed: up to 200mm/s

- Interchangeable nozzles (diameters from 0.30mm to 0.80mm)

- Integrated LCD control panel.

The Olivetti 3D Desk has a front 128x64 dot matrix LCD display. Here are the main printer operations controls that can be managed through the display:

- Nozzle temperature

- Cooling fan speed

- Flow Rate

- Print progress from SD card

- Printing time

- The status bar (status messages, and/or error messages)

- Printing Area 200 x 200 x 200mm

- Printing volume approx. 8 litres

- Available nozzle diameters: 0.30 – 0.40 (default) – 0.50– 0.60 – 0.80mm

- Minimum layer thickness: 0.05mm (50 microns)

- Precision tolerance, excluding material retraction:

- X-Y axes: 0.04mm (40 microns)

- Z axis: 0.01mm (10 microns)

- Extruder maximum temperature: 285° C

- Filament diameter: 1.75mm

- Full compliance with the safety requirements prescribed by the International Directives for Industrial Machineries (Machinery Directive 2006/42/CE (MD))

- Closed body structure with front panel lock

- The Olivetti S2 can produce objects using filaments of several thermoplastic materials, including PLA, High Quality PLA, Special Filaments

- However, the use of non-certified filaments could cause the extruder’s and nozzle’s clog, with consequent interruption of the operations and possible replacement of some components

- For this reason, we suggest the use of Olivetti filaments to guarantee the printer correct operations and the best quality of printed items.